Liquid cold plates are considered one of the high-power and high-end tools that play a very significant role in the heat dissipation of electric devices. They are widely used in different electric equipment which is high powered such as refrigerators, vehicles, and some other equipment.

For cooling, the temperature of the electric cold plates uses water circulation. Now here the reason for using water is the cost reduction, the heat capacity of water, and some other factors are also involved. The liquid cold plates have entered different fields. So you can find many typical applications for liquid cool plates here in the given article.

Principle of Liquid Cold Plates

The cold plates are adjusted on the top of the component where the cooling is demanded. The plates are designed in such a way that they can absorb and remove the heat from that particular component into the fluid that they have.

If we talk about the principle of the liquid cold plates in the heat removal of electric devices is very straightforward. It acts as a closed device where the liquid flows. As it is a piece of electric equipment so it is the power that circulates the fluid in this closed system.

These plates are responsible for transferring the heat from the source to the dissipation device with a good area of liquid circulation.

Applications of Cold Plates

With the passage of time, electronic components are reducing in size day by day. Overall the requisite density of those components has raised the need for cooling methods and now in electronics liquid cooling systems are the trending one.

The cold plate used has increased a lot in recent years. It is composed of a closed-loop system where a liquid needs to be circulated. This system is a common and successful way of cooling the device or managing the temperature.

The cold plates have a wide area of applications in different industries where high amounts of heat fluxes are involved or where high-temperature involvement is present. Now air cooling is not sufficient to control the temperature of such high-powered systems or components and we need here a method that is feasible like the use of cold plates.

They are typically used in industries to cool down the power devices and electronics that are present in the motors. It is also used to control the automation system of cooling on the large scale. It could be refrigeration or air conditioning, dryers, or boilers.

Some typical applications for liquid cold plates are described here:

- the refrigeration systems or buildings

- the heating systems or buildings

- the communication industry

- the laser equipment

- the medical types of equipment

- electric vehicles

- power supply industry

- Military industry.

Although it has different applications in different industries, the main purpose is the same. It is generally used to cool down power devices or the large-scale electronics and cooling systems

Emergence of Cold Plates

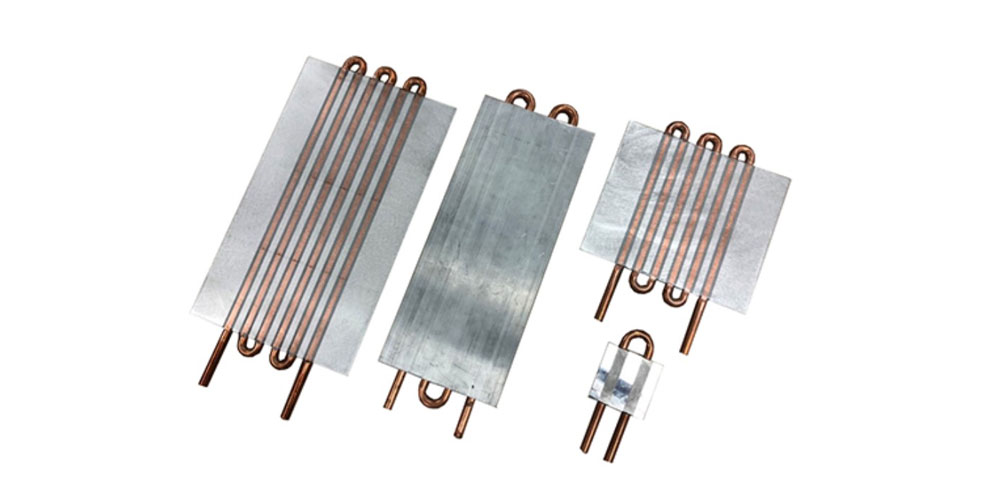

Cold plate technology is not a recently developed technology. It has been used for many years at their basic level in the past. We had liquid cold plates made from metal blocks, these have an inlet and outlet and inside the tube the liquid coolant is allowed to flow.

In this, all system liquid plates have their own specific role while performing their job they absorb the heat from the component into its liquid and then the heat is recycled.

It has two basic designs:

Internal Tubing:

Here the fluid flows simply in the tubes internal

Mini Channels or Micro channels:

Here the fluid flows through the channels

Both designs are developed in such a way that high pressure does not achieve but gets a high flow rate.

Conclusion

The liquid cooling system has proved to be very beneficial, especially in advanced devices and technology. Cold plates are widely used in different equipment that is either working on a large scale or a small one. They have applications in different fields inclined the military, refrigeration, and heat dissipation.